A Crisis of Waste in the Global Food Supply Chain

The agrifood industry faces a paradox: while over 800 million people go hungry, nearly 40% of all food produced globally goes uneaten—a staggering 2.5 billion tonnes each year(Source: WWF). Much of this waste happens before food even reaches consumers—during harvesting, storage, transport, and distribution (Source: FAO).

These issues are rooted in lack of visibility, fragmented logistics, and outdated processes. Thus, brands and distributors must face the question: how can we reshape the supply chain to ensure food is delivered efficiently, safely, and sustainably?

The solution lies in adopting a new model for distribution—one that leverages data and technology to track every stage of the supply chain, pinpoint potential issues before they escalate, and drastically reduce food waste.

This is precisely how fresh produce brand, SoLumi Fresh, is tackling the issue — leveraging end-to-end traceability and actionable supply chain data through the DiMuto Platform to ensure that fresh produce moves efficiently from farm to table, with minimal waste and maximum transparency.

Introducing SoLumi Fresh: A Brand Powered by DiMuto

SoLumi Fresh, a visionary brand powered by the DiMuto Platform, exemplifies how modern technology can directly combat food waste in the agrifood sector. Specializing in fresh produce, SoLumi Fresh uses DiMuto’s traceability tools to monitor every carton from farm to table—capturing images, quality data, and handling conditions at each stage to reduce loss and spoilage.

By digitizing the supply chain, SoLumi Fresh not only ensures product integrity but also empowers customers with easy access to verified data on the origin, journey, and environmental impact of their purchases—simply by scanning the label.

A New Era of Food Distribution Powered by DiMuto

Most traditional distributors operate in the dark, reacting to spoilage, delays, and customer complaints after damage is done. DiMuto flips this paradigm on its head.

Through an integrated Trade Management Platform powered by AI, blockchain, and carton-level QR tagging, DiMuto brings end-to-end traceability and real-time trade visibility to the global food supply chain. Every carton tracked on the DiMuto platform is seen, verified, and analyzed—from farm to fork—enabling timely interventions that prevent loss and waste before it happens.

In particular, DiMuto’s Product Quality AI is designed to tackle subjective and inconsistent quality assessments. By analyzing high-resolution images captured at packing using DiMuto’s digitization devices, the AI evaluates key visual attributes such as size, shape, color, and surface defects with speed and consistency that far exceeds manual inspections. This real-time grading capability enables producers and exporters to detect issues like under- or over-ripeness, damage, or non-conformity before goods are shipped, reducing the risk of rejections at destination. By ensuring that only products meeting buyer specifications are dispatched, Product Quality AI helps to significantly lower post-shipment waste, protect margins, and build trust between trade partners.

This level of visibility is extraordinarily rare in the fresh produce sector, which continues to suffer from inefficiencies and manual processes. DiMuto fills a critical gap in the market—the gap between growing food and ensuring it actually gets eaten.

SoLumi Fresh leverages DiMuto’s platform to monitor product quality at every stage of the supply chain. By capturing real-time images, logging condition data, and flagging handling issues early, SoLumi Fresh significantly reduces waste and rejections—ensuring more produce reaches consumers in optimal condition.

This approach not only helps to reduce waste but also sets the stage for the future of food distribution—one where brands take the lead in driving change. Today, brands are expected to do more than deliver a product; they are responsible for ensuring it is handled sustainably and efficiently throughout its journey. By adopting DiMuto’s solution, brands like SoLumi Fresh are redefining what it means to be a responsible distributor in the modern agrifood industry.

Real-World Impact: Sweet Potato Case Study

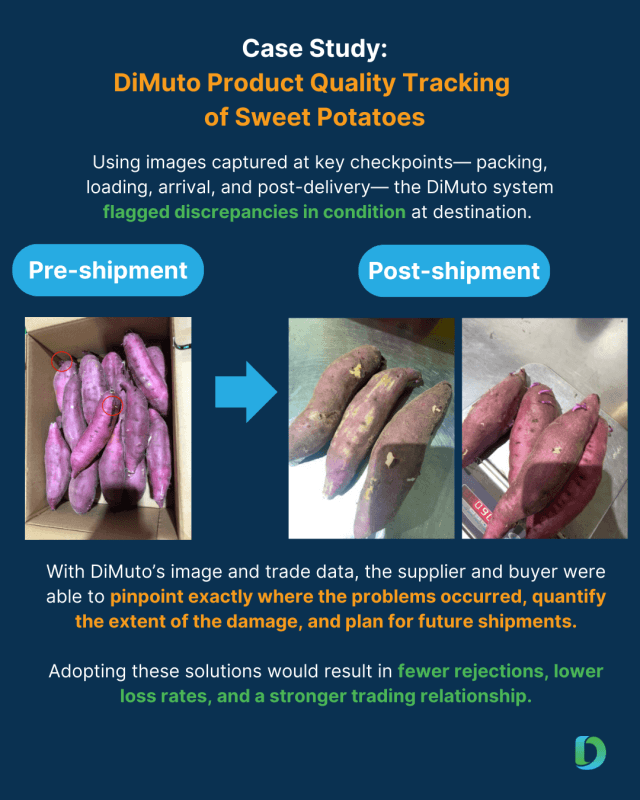

To understand how this works in practice, let’s look at a previous shipment of sweet potatoes.

DiMuto tagged and tracked each carton from origin to final destination. Using images captured at key checkpoints—packing, loading, arrival, and post-delivery—the system flagged discrepancies in condition at destination.

Quality degradation was traced back to two main issues:

- Pre-shipment: Quality inspection check was insufficient, allowing defects such as early sprouting and incorrect sizing to go unnoticed

- Packaging: Size of the box was too large, leading to shifting and surface damage during transit

With DiMuto’s image and trade data, the supplier and buyer were able to pinpoint exactly where the problems occurred, quantify the extent of the damage, and plan for future shipments—including improved quality inspection protocols, and new carton measurements. Adopting these solutions would result in fewer rejections, lower loss rates, and a stronger trading relationship.

Leading the Change & Closing the Loop

As food waste continues to be one of the most pressing issues in the global supply chain, it’s clear that traditional methods are not enough. The future of food distribution lies in innovation—and DiMuto is at the forefront of this change.

Through its platform, DiMuto enables brands to take control of their supply chains, reduce food waste, and ensure that food reaches consumers in its best possible condition. As the industry continues to evolve, brands must embrace this new model of distribution, not only to improve their bottom line but also to contribute to the broader goals of sustainability and food security.

By adopting data-driven, transparent, and traceable solutions, brands will not only meet the challenges of today’s food supply chain—they will help shape the future of the global food industry.