PRODUCE QUALITY ASSURANCE AI SOLUTION

Power AI-verified quality control at every stage of your produce supply chain

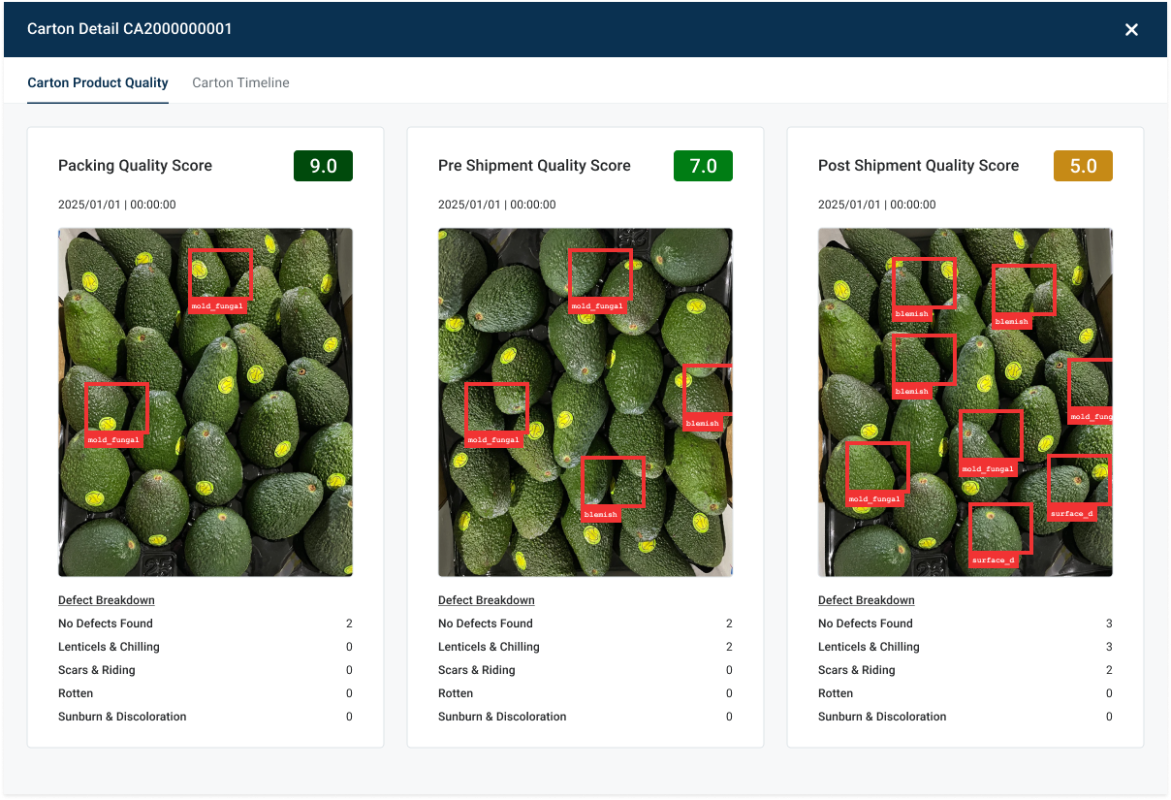

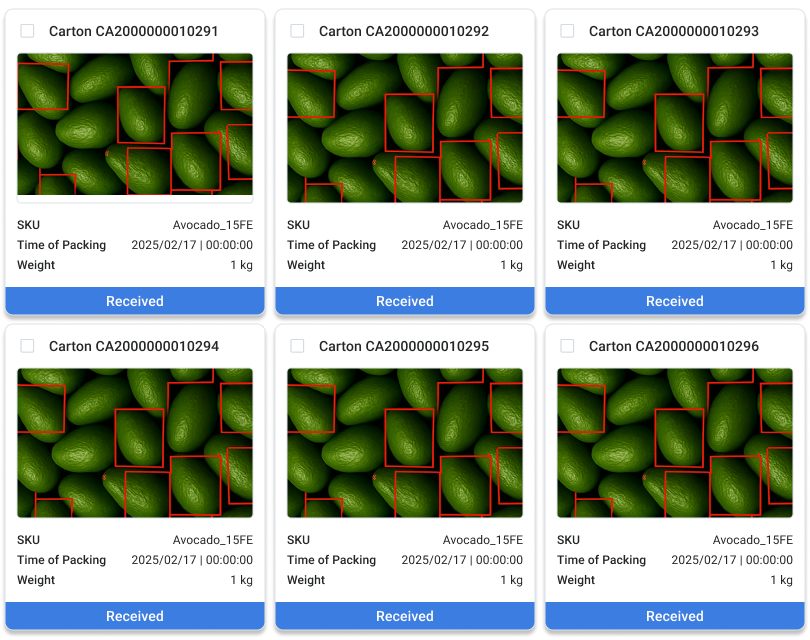

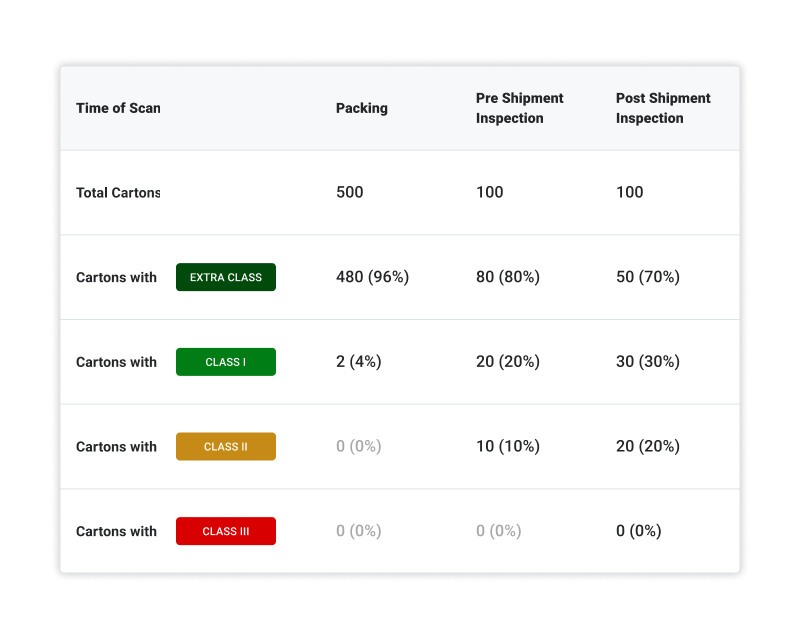

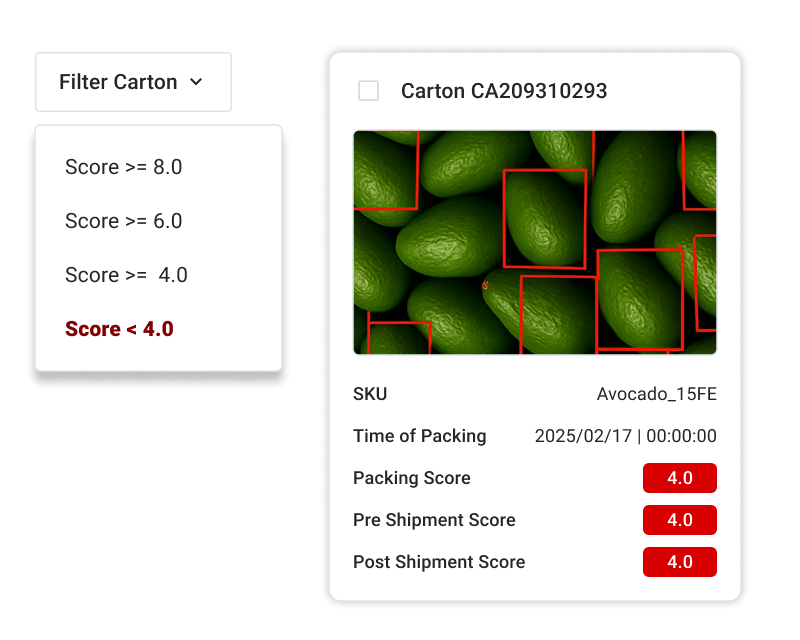

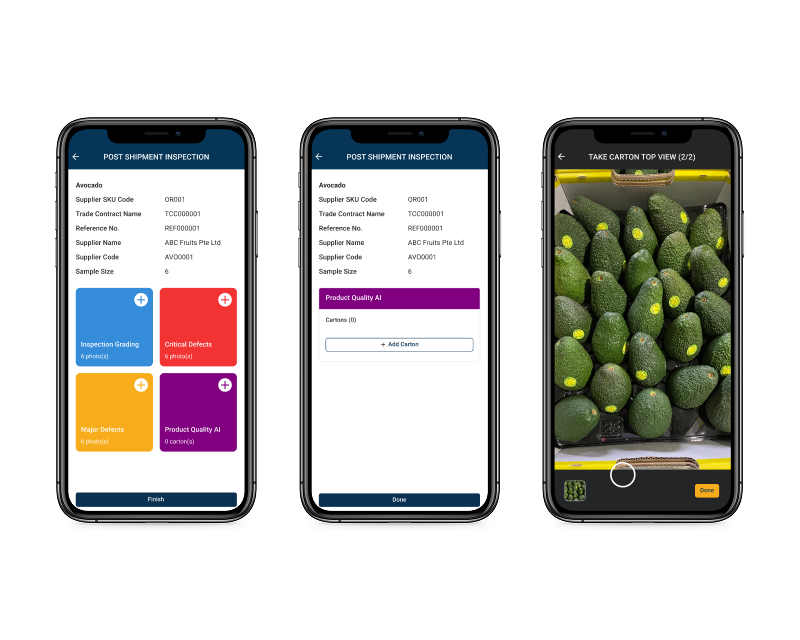

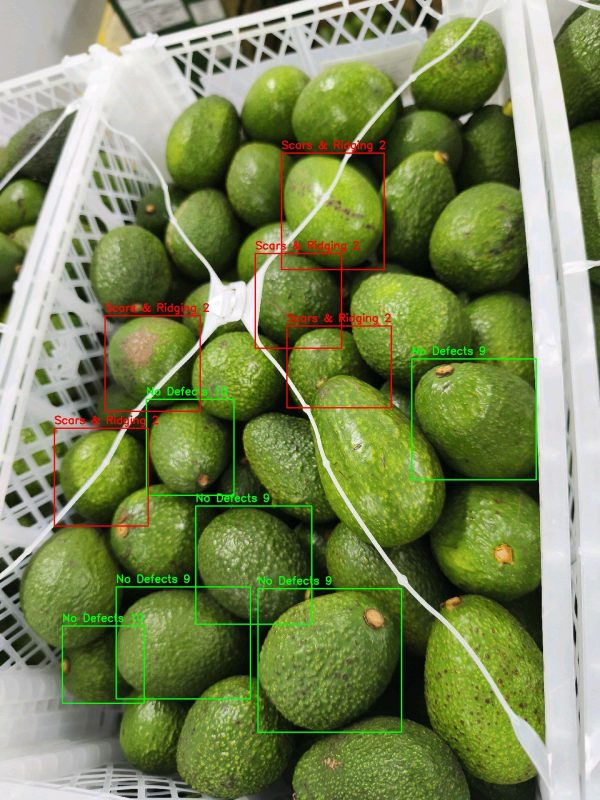

Fresh produce quality is unpredictable, manual checks are often slow and inconsistent. With DiMuto PQAI, every carton can be instantly analyzed by AI at packing, pre-shipment, arrival — delivering consistent, real-time quality control that reduces disputes, improves accuracy, and protects margins.