This is the second article in the series “The Digital Supply Chain”. This series explores what is digitalization, reasons for digitalization and best methods for digitalization of agri-food supply chains.

Managing agri-food supply chains is notoriously fraught with challenges. Today, global agrifood supply chains are extremely complex, as agricultural products such as fresh produce often pass through many different stakeholders and cross international borders before finally reaching the end consumer.

The current modus operandi of modern agrifood supply chains often means that information stored at one layer of the supply chain remains accessible only at said layer. For instance, information regarding the sorting and packing process of fresh fruits into different cartons often stays at the packers – meaning only the packer knows how were the fruits sorted and what was packed and shipped for each carton.

This often results in a disconnected visibility of the supply chain where companies are unable to track products as they move across borders – creating what we in the industry call the “Messy Middle” where miscommunications, misinformation and trade disputes thrive due to the lack of data and information flows. Due to this lack of transparency, packers and suppliers find themselves facing heavy burden of proof when it comes to proving that they have packed produce of order-specified quality to buyers and retailers.

The Messy Middle of agri-food supply chains

The Messy Middle of agri-food supply chains

The Unspoken Challenges of The “Messy Middle”

Operating in the “Messy Middle” is a giant nightmare for both buyers and suppliers alike. Currently, the information flow for each trade is all over the place, made more complicated with the onslaught of country-preferred instant messaging applications. Sales teams often communicate through both messaging applications and email threads, making transactions prone to miscommunications and misinformation.

Without a single trusted platform acting as a unifying depository of sales and product information categorized according to each trade conducted, internal company resources like manpower and time are predominantly allocated towards coordinating, tracking and tracing sales orders, shipping documentation, and financial payments.

With the different communication channels, there is no way to verify, find and share information in a timely and efficient manner.

This becomes a huge problem when quality disputes over goods received are raised. A Chinese apple supplier receives a quality complaint for a container order of Fuji apples from its buyer in Indonesia – “there’s a problem with the apples for order number 123, they are of poor quality”.

Now the apple packer faces an overwhelming burden of proof in trying to show that they have indeed packed their apples to the specifications of said order, as all the information regarding the trade is all over the place, and this trade dispute resolution process is only beginning to happen after the packing, transporting and receiving has been done.

Because suppliers often find it difficult to prove what happened at the point of packing, professional quality control groups are often hired in order to provide a “fair” evaluation of the quality of the products, adding yet another cost of doing the trade.

Disputes often translate to a drastic loss of margins of up to 5 – 10% per container, amounting to as much as $2,500 to $5,000, which is why such a problem is often swept under the rug. Nobody wants their competitors to know they are not doing well or there was a supposed problem with their product. Hence, a key unspoken challenge remains for players navigating this “Messy Middle” nightmare

Hear our founder explain the problems of the produce business here

Blockchain Touted As Revolutionary Supply Chain Technology

That’s why blockchain technology has come under the spotlight recently for its application to the supply chain industry.

Blockchain can publicly validate, record, as well as distribute transactions in immutable, encrypted ledgers.

With its ability to upload immutable trade documents, blockchain has the potential to share verified documents relating to each trade in a secure and efficient manner.

This means that that custody of truth is no longer with one single party within each trade, but instead, trade partners now look towards the blockchain as a source of truth and verified information.

This is also especially valuable when it comes to entering new markets and working with new buyers and suppliers. Having a single, shared platform where information on it is trusted by both parties significantly reduces the friction of conducting business.

With blockchain, buyers and suppliers can now see and agree upon the order specifications that was finalized between both parties, as well as access to relevant product information such as health certificates necessary for exports.

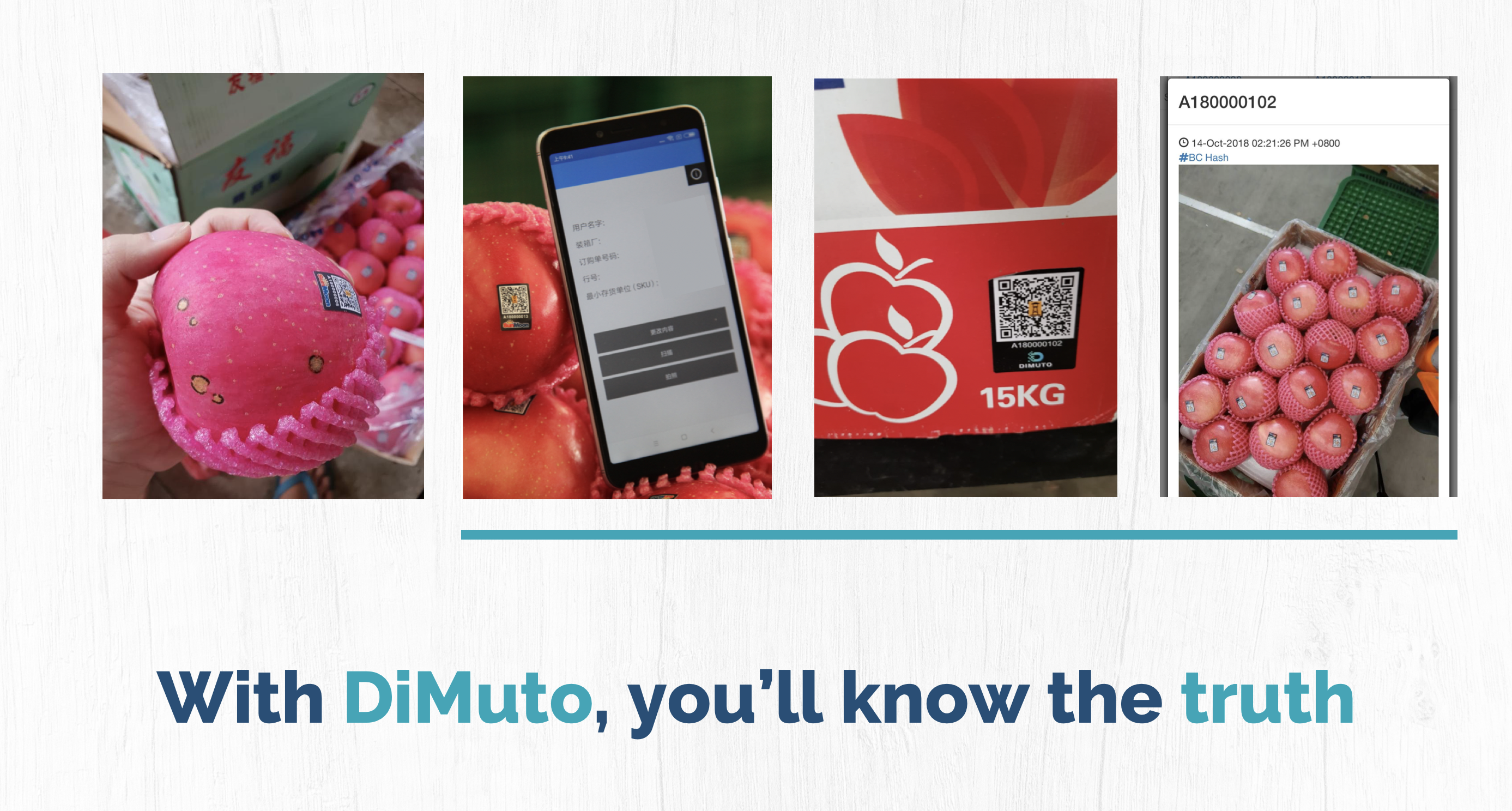

DiMuto goes a step further beyond blockchained trade documentation by providing physical asset digitalization – meaning we assign a digital identity to every single physical produce, and are able to capture a photo of each carton and product before each carton is sealed, upload this photo and associate it to the specific sales order it was packed for. (We previously explained what constitutes a digitalized produce here)

Our proprietary Digital Asset Creation machine, affectionately named DACky

Our proprietary Digital Asset Creation machine, affectionately named DACky

The moment a physical asset like fresh produce can be digitalized, businesses can easily track not only the movement of the product but also critical product information such as quality, health certificates, certificate of origins, product photos tagged to the specific individual product, as well as relevant trade documents surrounding each supply chain transaction.

Such data is first captured in secure, sequenced blocks of information under the productʼs digital identity and automatically uploaded onto our blockchain-powered Track & Trace Trade Platform.

Photo of DiMutoed apples for a specific carton that had a quality dispute (Read more here)

This means packers and suppliers are now able to see the quality of the product before the products are shipped off, and access the information easily according to each sales and purchase order – greatly relieving the previous burden of proof and reducing trade disputes.

Proving The Error and Not Error-Proofing

However, it is important to note that blockchain platforms built for trade transparency shouldn’t aim to completely eradicate errors.

An error-proof system would mean greater rigidity and potentially be more costly to upkeep, and less scalable due to the operational differences between individual packers and suppliers.

As Nick Szabo, an eminent computer scientist and cryptocurrency expert, once said, “Blockchains don’t guarantee truth; they preserve truth and lies from later alteration”.

That’s why at DiMuto, we have designed our platform in a way that’s easy and intuitive for industry players to use while achieving the primary purpose of blockchain for supply chain transparency.

If you are interested to learn more about how DiMuto helps create traceability for fresh produce, please reach us here or drop us an email at [email protected].