DiMuto recently digitized avocados from Peru coming into Singapore and helped create a new level of visibility for the avocado trade. Read on to find out how did DiMuto help to solve challenges of moving produce with no visibility.

The Challenge: Operating in The Land of The Blind

What happens in the fresh produce trade every day? Currently, global produce trade is being conducted with little to no visibility of the supply chain, leaving plenty of room of mistakes that create a heavy burden of proof faced by suppliers when things go wrong.

Global Popularity of the Avocado

The avocado is one of the most popular fruit in the world. In 2017, FAO estimates that the global production of avocados reached 5.71 million tonnes.Avocados are grown mainly in the Southern hemisphere and have to be transported thousands of miles to consumers all over the world – In 2018, according to FreshPlaza, the world imported 2.5 million tons of avocados worth $ 6.1 billion dollars.

Ripeness is critical for fresh avocados

Due to the transit time, it is essential for avocados to be transported in optimal cold chain conditions to maintain freshness of the fruit that can extend the shelf life of avocados by 2 weeks.Avocado transportation differs for each market, and for different seasons, with recommended storage and handling temperatures ranging between 3.3°C – 6°C from Mission Produce. Low maturity fruit will maintain its quality and shelf life at slightly warmer temperatures such as 5.5°C whereas cooler temperatures around 3.3°C will extend shelf life of ripe avocados.Ripeness is determined visually with the skin colour and markings on the avocado. Buyers would need the avocados to be as green as possible. Visual inspection of skin colour is done to determine freshness and there is typically a tolerance of est. 5 – 10% for markings and spots.

The Messy Middle Nightmare Begins – “Your Avocados Are Too Ripe”

For the avocado, a hugely popular fruit, tonnes and tonnes are moved across borders every day with no visibility once it leaves the packinghouse.Thus, it is not uncommon to end up in trade disputes similar to the situation that our Peruvian supplier faced:

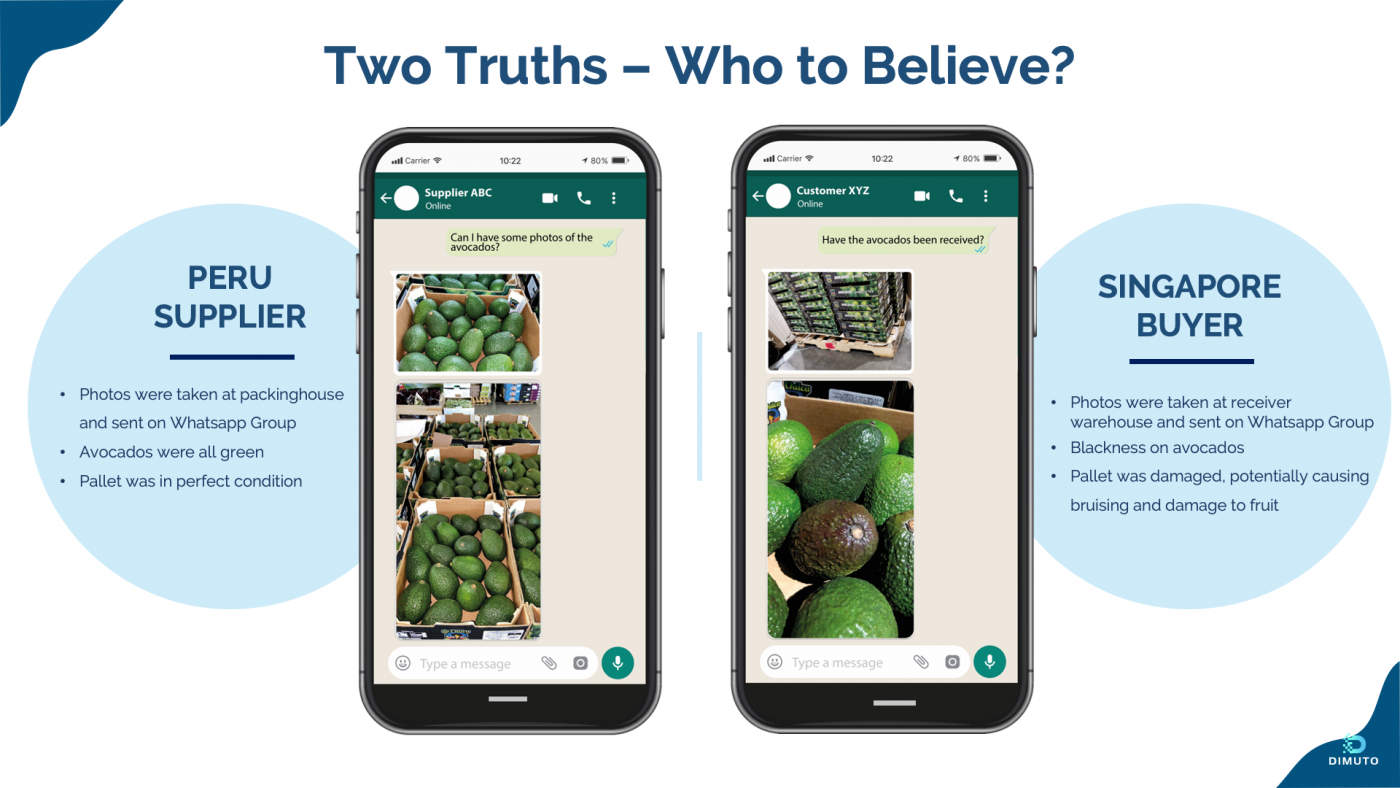

At the buyer’s request, the supplier submitted photos of the carton of avocados that they were selling to the buyer through the Whatsapp Group they were in. The photos showed that the avocados were all green and that the pellet was in perfect condition.However, upon arrival, the Peruvian supplier received photos showing that the avocados were too ripe, and that the pellet was damaged, potentially causing bruising and damage to the fruit.

No Data, No Visibility

Suppliers are unable to show what, where and how the trade went wrong. With no data, suppliers often bear the cost of such errors.For this avocado trade, the peruvian supplier was:

- Unable to verify when the good was received

- Unable to verify which carton had the issue

- Unable to verify if damage was done by logistics 3rd party

Such trade disputes can cost suppliers up to 5-10% of every trade.Becoming The One Eyed King

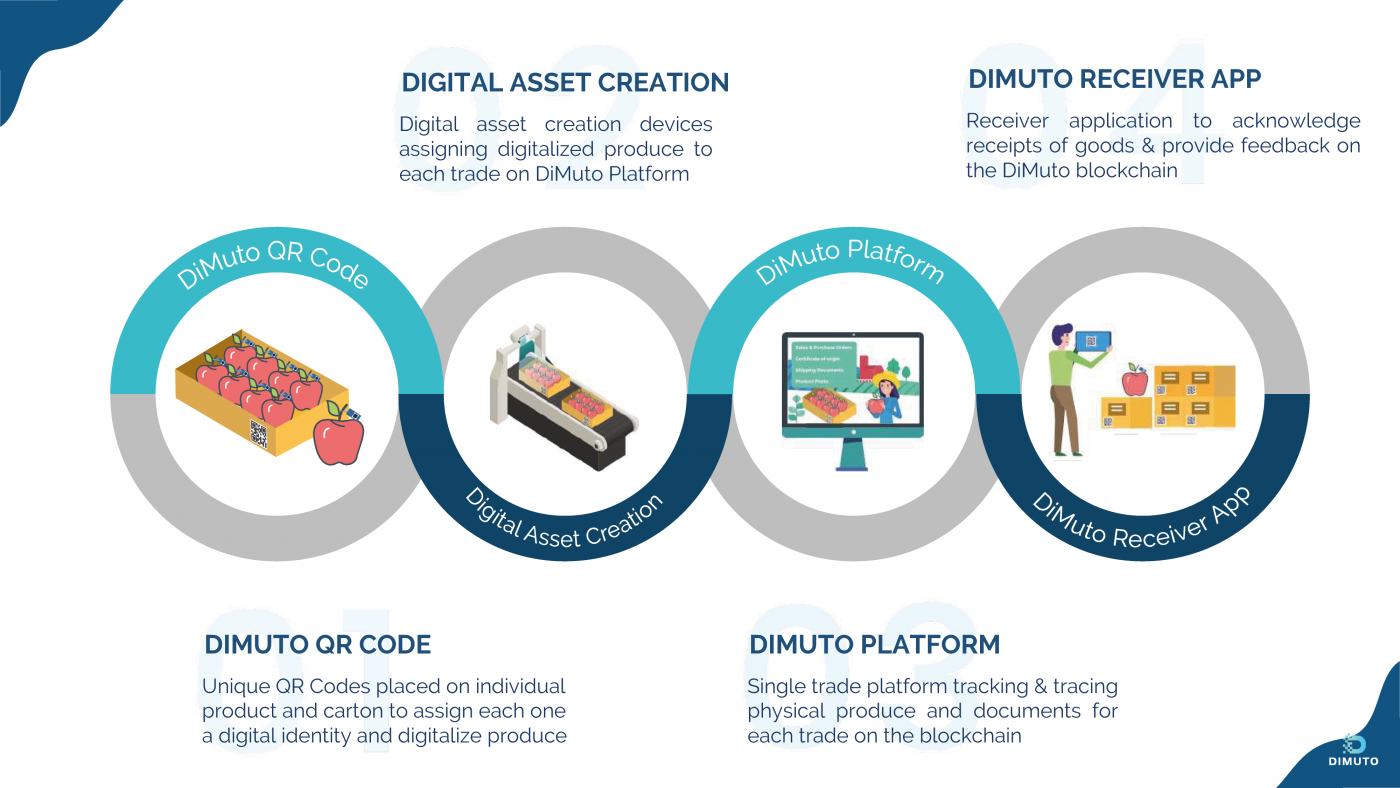

Created by trade for trade, DiMuto brings visibility to the agri-food trade.Using the DiMuto 4T Suite Solution, a 4-part trade technology solution combining blockchain, AI and IoT, DiMuto digitalizes the agri-food supply chain for data visibility and trade transparency, aiming to solve the industry’s various challenges such as food waste, food safety and food sustainability.The DiMuto 4T Suite Solution creates traceability for every single fruit as they move through the supply chain by capturing important data at key supply chain stages. Individual products and cartons are tagged with DiMuto QR codes to assign each one a digital identity. These products and cartons are then digitalized through DiMuto’s proprietary Digital Asset Creation devices (DACky). Buyers can then use the DiMuto Receiver App to acknowledge the receipt of goods and provide feedback, all recorded on the DiMuto Platform to truly close the supply chain loop on one single platform. With the visibility provided by data captured as the product moves through the supply chain, DiMuto helps to reduce disputes over quality and creating trust amongst trade parties.

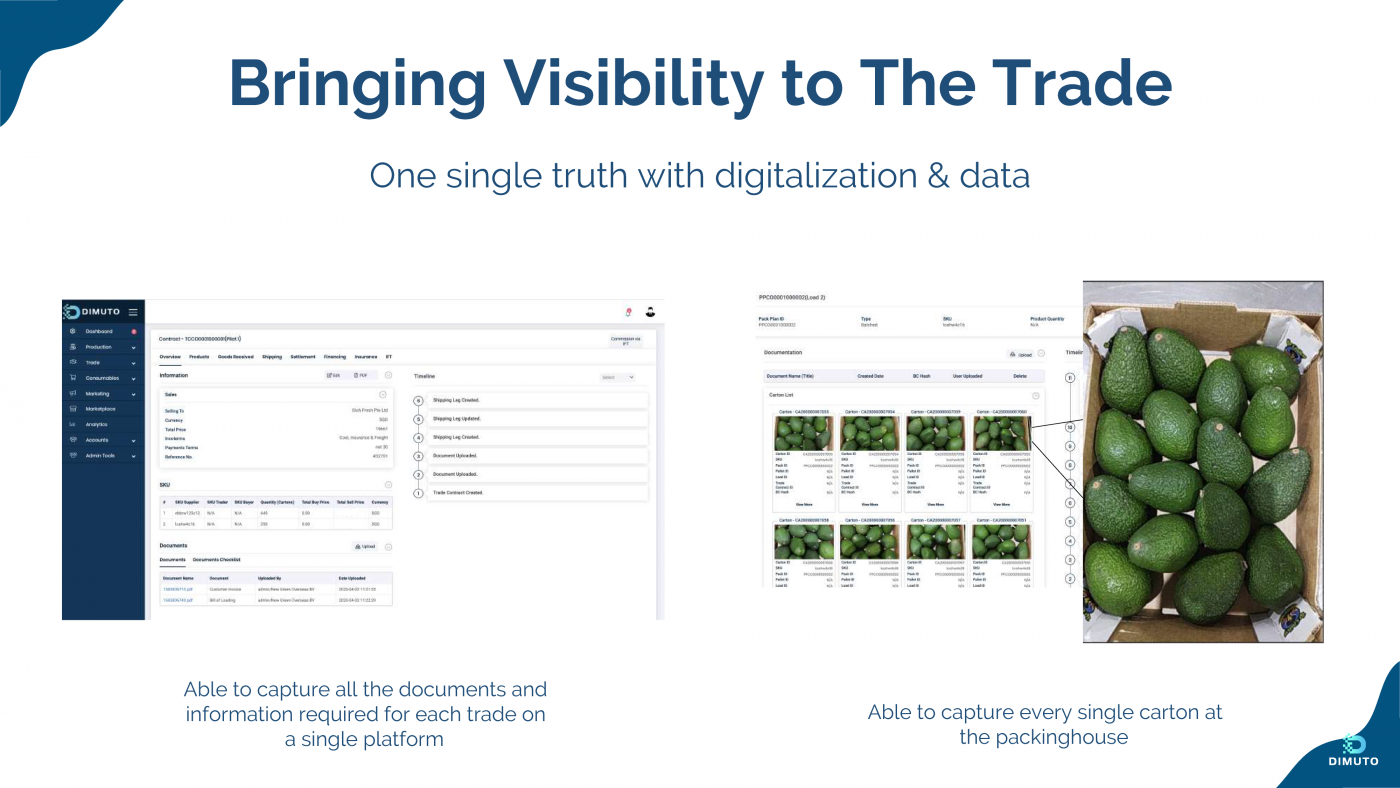

Easily track & trace every single carton and every single produce for all your produce trade using DiMuto 4T Suite Solution DiMuto helps provide increased supply chain visibility for both suppliers and buyers:

- Receipt of goods and feedback done on a single platform

- Able to track quality issues down to individual cartons

- Easily access product photo and related trade documents

Using our solution, the Peruvian avocado supplier is able to show that they did indeed sell avocados in good condition to the buyer by tracking the product photos on our DiMuto Platform.If you are interested to find out how DiMuto can help your business, please reach us here or drop us an email at [email protected].

Download the one page summary of the case study here.Download our full case study PDF here.