Pandemics are characterized by their severe negative consequences on the global economy. COVID-19 has had a significant influence on one of the most vital areas of the economy – the whole food supply chain, from the source to the consumer. The disruption to supply networks continues to be severe, with the virus continuing to cause numerous areas and economies impose lockdowns and restrictions, while others struggle to adapt to a post-pandemic landscape. The supply chain will be crucial in providing products and services promptly, reliably, and securely as economies begin to recover.

COVID-19 is causing the ‘Messy Middle’ in operations to be more challenging throughout the world in ways that are difficult to predict and measure. Agri-Food businesses are concerned that they will not be able to meet contractual commitments on time due to the new challenges posed by the pandemic and the lack of visibility; from Supplier to Retailer to End-Consumer. There remain substantial concerns regarding food production, processing, distribution, and demand in lieu of pandemic-related supply chain changes such as limitations to workers’ mobility, changes in consumer demand, the closure of food production facilities, new food trade laws, and financial constraints in the food supply chain.

In addition to the new obstacles posed by the pandemic, COVID-19 revealed previously unknown weaknesses in several sectors – Lead Times, Lack of Diversification and Visibility, and many organizations have experienced heavy losses because of it, exacerbating and hastening issues of the ‘Messy Middle’ that previously existed in the supply chain.

How The Pandemic Impacts the Global AgriFood Supply Chain

From farm to fork, there are five phases of the food supply chain (FSC). Two mechanisms are used in the food supply chain for food consistency and protection. The first focuses on rules and legislation that use mandatory requirements reviewed by government agencies. The second focuses on voluntary principles established by economic law or international organizations. FSC contains important final stages that can easily affect end-consumers. This includes safe food handling, preparation, delivery, the use of personal protective equipment such as helmets and gloves, surface disinfection, and work. Maintaining environmental and even social distance are some safety measures implemented to ensure the continuity of food flow.

The Covid-19 pandemic, unlike foot-and-mouth disease, avian influenza, and Listeria, does not directly infect animals or produce and therefore has no impact on development of diseases via produce. However, because of the pandemic, nations have severely restricted the flow of goods (land, sea and air transport) and the movement of labour around the world to manage and control the rate of transmission of Covid-19 between people.

Reportedly, Australia’s isolation rules have also created shortages of workers to harvest, pack, transport and distribute the fruit and vegetables which leads to strained distribution of food supplies. These conditions are aggravated with Uganda’s authorities demanding fresh testing of Covid-19 by the Kenyan truck drivers upon their arrival at the border with claims that their Covid-19 certificates are falsified, enabling the Truck Drivers to go on a strike due to the stated conditions. These situations greatly delayed the supply of fresh produce.

Chile Scrambles to Regain China’s Confidence on Cherry Imports

Chile’s association of fruit exporters Asoex stated that wholesale purchases of Chilean cherries have decreased to 4% below normal levels in 2021 and retail sales flopped heavily by 63% in China.

The cause of reduction for cherry imports in China is due to reports that have been made stating that some imported cherries tested positive for traces of the coronavirus in Jiangsu Province, which swiftly spread across the Chinese media making the consumers doubt and lose confidence in purchasing them. This incident impacted the cherry sales negatively as cherry sales suffer a devastating blow due to the fear of being contracted with the Covid-19 virus.

COVID-Driven High Freight Rates Makes Receiving Poor Quality Fresh Produce More Costly

According to the Xeneta Shipping Index, there has been an increase in freight rates, with global container prices rising by 3.2% in September 2021, which marks an astounding surge of 91.5% as compared to the previous year. As the costs are high in shipping fresh produce, receiving poor quality fresh produce would further incur loss in sales where a container of Fresh Produce can value between US$50,000 to US$150,000 and wasted costs that are not easily recovered where rises in freight costs are at an all-time high making goods rejection even more costly.

How DiMuto Helps AgriFood Companies Stay Resilient

DiMuto understands the many difficulties in conducting cross-border international agrifood trade, and the various risks involved, due to the disconnected flow of information across global supply chains where buyers and suppliers are often located in very distant geographical areas.

With DiMuto and our trusted network of buyers in the region, you can trade Agri-Food products and fresh produce products with seamless visibility and accessibility. DiMuto’s Global Trade Network is made up of an exclusive network of trusted buyers and suppliers conducting traceable trade on the DiMuto Platform. With full supply chain visibility, growers and retailers can buy & sell fresh produce more effectively and efficiently.

For Buyers:

When retail stores receive goods that do not fulfil order specifications or products that have some form of quality issues. Moreover, the defects are only known when the fruit or produce has arrived due to a lack of product visibility along the supply chain. This makes trade managing fresh produce challenging for retailers:

- Unable to see pre-shipment product quality and container loading

- Unable to quickly respond to inventory changes due to rejections from quality defects

- Unable to communicate defects easily and effectively between internal teams

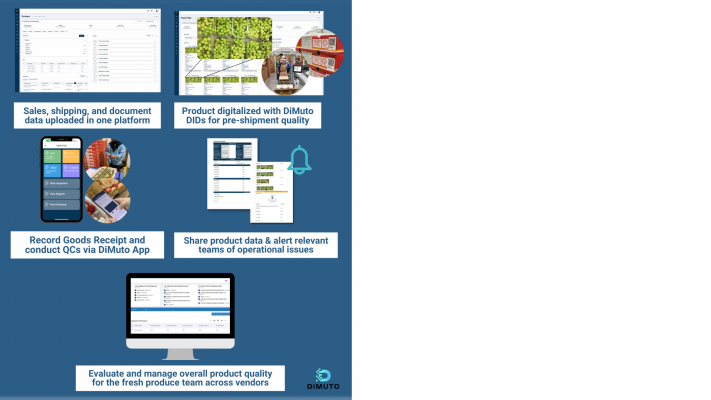

With DiMuto, Retailers can now enjoy accessible visibility of pre-shipment and post-shipment quality to better manage any potential loss of sales

- Pre-shipment product quality down to every single carton easily accessible to commercial team

- Trade information, documents and actions of each trade seamlessly recorded and presented in timeline view

- Post-shipment product quality efficiently captured and communicated between QC, commercial and retail teams

- Dashboard view of Inspection Management to ensure optimal product quality and vendor performance

Read more on How Retailers Can Better Manage the Impact of the ‘Messy Riddle’

For Suppliers:

By joining DiMuto’s Global Trade Network, you will deal with traceable, trackable fresh produce that has been digitized TradeTrust Blockchain Validation, creating data-backed trust and peace of mind when you conduct global produce trade adapting to the pandemic that has disrupted trade.

Read more on How DiMuto Uses TradeTrust Blockchain Validation to Strengthen Trust in Global Trade

Pukuna Farms Using DiMuto’s Traceability for Visiblity and Accessing New Markets

Based on a challenge faced by one of our customers – Pukuna Farms, they were finding a way to expand their market to such an unknown region like Asia, hailing all the way from Ecuador. It is not easy to enter an unknown market and for that, the supplier has to be reliable, where consistent quality is key. Buyers need to be assured that suppliers will sell their fresh produce in good condition and they will be receiving the products as per specified and upon the arrival of the fresh produce and buyers will be required to scan the fruits for visibility on the quality of fruits. For that, it is important to have full visibility in the supply chain.

With DiMuto’s traceability solutions, traceability and digitalization secured with Blockchain-Powered solution, Pukuna Farms was able to improve in sales as each Pitahaya is digitalized with DiMuto QR code so it can be tracked and traced on one single platform to provide full visibility as it moves through the supply chain, making it easier to manage trade dispute based on the information recorded timely on the DiMuto platform.

Product quality, farm information and trade information are captured on the DiMuto platform. Thus, the visibility provided by DiMuto to supply chain partners enables trade traceability and transparency, improving trust and establishing long lasting partnerships between supply chain partners.

Read more on how Pukuna Farms Uses DiMuto’s Traceability.

DiMuto Creates Trade Visibility for “The Messy Middle”

DiMuto’s Accessibility of Pre-Shipment and Post-Shipment Quality

With DiMuto, Retailers can now enjoy accessible visibility of pre-shipment and post-shipment quality to better manage any potential loss of sales

- Pre-shipment product quality down to every single carton easily accessible to commercial team

- Trade information, documents and actions of each trade seamlessly recorded and presented in timeline view

- Post-shipment product quality efficiently captured and communicated between QC, commercial and retail teams

- Dashboard view of Inspection Management to ensure optimal product quality and vendor performance

Fundamental shifts in consumer behaviour, supply networks, and routes to market have made Agri-Food companies face challenges in adapting and resolving them. As a result of the pandemic, companies must expedite the implementation of efficient solutions to navigate the unpredictability.

If you are interested to learn more about how DiMuto helps Agri-Food businesses leverage on an increased visibility to stay resilient amidst the challenges of the pandemic in the supply chain, please reach us here or drop us an email at sales@dimuto.io.

Español

Español 中文

中文